18 February 2026

Printed Electronics in Mountain View, California

When: 10 & 11 June 2026 Where: Computer History Museum, Mountain View, California Register before 15 March 2026 for early bird rates The Largest and Most Important Additive Electronics Show in North America! This is the most important and the largest conference and exhibition in North America dedicated to additive, printed, flexible, hybrid, wearable, stretchable, soft electronics. Exhibition floor : Almost sold out. Agenda: Shaping up to be our strongest yet. Featuring: NextFlex Innovation Days Co-locating: Wearables RESHAPED Exhibition Floor Almost Sold Out The exhibition floor is almost sold out with over 90% of the available spots booked. Act now and book your place! Visit here to download the info package including detailed pricing and benefits descriptions. Tom Keenan will also be your primary point of contact (tom@techblick.com) The Only Truly Global Package Worldwide Our packages are the only truly global option, combining the opportunity to exhibit in the USA and Europe with year-round global digital marketing and engagement. The key benefits include: Onsite exhibition (California and/or Berlin shows) 2 or more full onsite conference & exhibition passes 6 or more annual online passes Onsite talk (silver and gold packages only) Online talk Email marketing Social media support Virtual booth...

13 January 2026

Conductive Technologies | Engineering Functionality: The Power of Sensors in Modern Applications

To watch this presentation in full, please purchase TechBlick Annual Pass at https://www.techblick.com/registration and login to TechBlick platform https://app.swapcard.com/event/techblick Engineering Functionality: Sensors Sensors are at the heart of modern technology - integrated into devices we use every day to enhance healthcare, fitness, safety, and comfort. From monitoring vital signs to enabling smart industrial systems, sensors are transforming the way we interact with the world. Depending on the application, sensors come in many forms, each with its own materials, requirements, and performance considerations. Below are a few examples of sensors that are key to next-generation sensor innovation. Biosensors & Electrochemical Sensors: Measure biological and chemical reactions by generating signals proportional to analyte concentration. PTC Heaters: Regulate temperature through self-limiting properties that enhance safety and efficiency. Temperature Sensors: Monitor and maintain optimal conditions using precise electrical signals. We are Exhibiting in California, USA. Visit our booth at the TechBlick event on 10-11 June 2026 . Contact us for your special discount coupon to attend These sensors find use across wearable , diagnostic , and industrial applications, each with distinct design and material needs: Wearables Flexible and stretchable materials Stretchable inks Adhesive layers (for housing-to-patch or multilayer adhesion) Conductive skin contact layers Dia...

13 January 2026

Transparent Touch Applications Using Pedot. Printed Circuits For Flexible Hybrid Electronics

Printed electronics often involve touch applications on flexible transparent films, which creates a demand for transparent conductive materials. Integration of ICs enables the control of capacitive touch functionality, combined with serial communication protocols such as I2C or USB. This allows for much smaller and more efficient connections than traditional solutions using bulky cables. DoMicro is capable of making Flexible Hybrid Electronic touch applications with screen-printed transparent PEDOT electrodes, inkjet printed silver circuitry and Anisotropic Conductive Adhesive ( ACA) bonded components. This paper focusses on the integration processes of printed transparent conductive polymer polyethylene dioxythiophene (PEDOT:PSS). Human machine interfaces and control displays should be easy to understand for the operator. Highlighting essential information depending on mode or status of the equipment creates a focussed and minimal atmosphere without distraction. Visual appearance and coloured feedback of touch icons by RGB controlled backlight LED’s is featured by transparent capacitive touch technology in Flexible Hybrid Electronics (FHE) circuitry. A FHE-Touch foil integrated with a FPCA-LED assembly enables a fully flat, flexible interface system that can be integrated in curve products and surfaces. Touch icon buttons can be completely hidden or made invisible when backlight is switched off. Figure 1 - User interface by Metafas Application demonstrator Figure 1 shows a...

6 January 2026

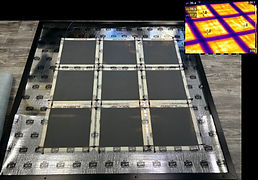

Blackleaf | Water-Based Graphene Inks: A Sustainable Innovation for Thermal Heating Elements

Authors: Anaghim Nasri, R&D Engineer Quentin Maerklen, Process Engineer Water-based graphene inks are emerging as a groundbreaking solution for next-generation heating technology. By leveraging graphene’s exceptional thermal and electrical conductivity, these inks enable thin, flexible heating elements that deliver high heat output with minimal power. Importantly, sustainability is becoming a key market driver, with growing demand for water-based, responsibly sourced graphene inks as eco-friendly alternatives to metal-based conductive materials. This article explores how water-based graphene inks provide efficient and uniform heating, their environmental advantages over conventional carbon-based inks, and the role of Blackleaf in driving this innovation forward. As the demand grows for eco-friendly heating (from automotive seats to building systems), water-based graphene inks offer a powerful combination of performance, sustainability, and scalability. Introduction: Blackleaf Inks for Next-Generation Heating One of the pioneers bringing this technology to market is Blackleaf, a French graphene manufacturer and ink developer. Blackleaf has positioned itself as a leading producer of graphene and formulated inks in Europe, with a capacity of over 120 tons per year of graphene products by 2027, all produced in-house in France. Blackleaf’ s product portfolio includes ready-to-use graphene conductive inks for a variety of uses. Notably, the company has focused on graphene-bas...

20 January 2026

Future of Electronics RESHAPED USA

When: 10 & 11 June 2026 Where: Computer History Museum, Mountain View, California https://www.techblick.com/electronicsreshapedusa Join us and 600+ others from around the world next June at the heart of the Silicon Valley to RESHAPE the Future of Electronics together, one layer at a time, making it Additive, Printed, Sustainable, Flexible, Hybrid, Stretchable, Wearable, Textile, Structural, 3D... This event stands as the largest show in the USA dedicated specifically to Additive, Printed, Hybrid and 3D Electronics. It unites the entire global community—connecting end-users and manufacturers with equipment providers, material developers, and applied researchers. The 2026 edition is expected to welcome more than 600 attendees and 80 exhibitors , supported by three parallel conference tracks , alongside masterclasses and technical tours designed to bridge innovation with real-world deployment. A major highlight for 2026 is the partnership with NextFlex , the US-based consortium at the centre of the Printed and Hybrid Electronics ecosystem. The inclusion of the NextFlex Innovation Day further strengthens the event’s position as the definitive North American meeting point for the community. “Electronics RESHAPED USA has firmly established itself as the premier event for our industry in North America, consistently selling out year after year. This is now the home of Printed, Additive, and Hybrid Electronics. By bringing the show to the heart of Silicon Valley for the firs...

13 January 2026

What Is Electronics Encapsulation?

Electronics encapsulation refers to the process of enclosing and protecting electronic components, circuits, or chips in a durable material or “package.” The encapsulating material (sometimes called a molding compound or potting compound) serves as a barrier against environmental factors like moisture, dust, and harsh chemicals, and shields the device from mechanical stress and vibration. Over the decades, encapsulation approaches have evolved significantly. Historically, hermetic encapsulation (a method of sealing sensitive electronic components inside airtight metal or ceramic enclosures) was common, as it completely blocked moisture and gases. This was especially important in aerospace or military-grade devices [1]. Since the 1970s, the industry has shifted toward polymer-based plastic encapsulation due to its low cost, ease of processing, and high throughput. Today, encapsulating components usually involves applying polymer resins (epoxies, silicones, polyurethanes, etc.) using automated dispensing, molding, or conformal coating systems. Common types of encapsulation Potting electronics Schematic of an encapsulated PCB assembly, adapted from © Hu C., et al ., CC BY 4.0 In the context of electronics and semiconductors, potting and encapsulation are often used interchangeably. Potting is an encapsulation process where an entire electronic assembly or a larger section of a circuit is placed into a mold (often referred to as a “pot”) and then filled with a potting material ...

12 January 2026

Introducing LMA Edge - An event that puts technology at the heart of lending

10 Feb 2026 | London | Free event Technology is reshaping every aspect of our lives, and the loan ecosystem is no exception. Advances in emerging technologies within the loan market such as Generative AI, Legal Tech, and Distributed Ledger Technology (DLT) are driving a wave of innovation, automating previously manual tasks, streamlining documentation, and enhancing transparency across transactions. But the critical question remains: how do we adapt, adopt, and utilise these solutions? LMA Edge is a brand new event dedicated to showcasing new technologies in the lending sector. It prioritises interaction, offering high-impact networking opportunities through exhibition, tech demos, case study and collaboration stage talks, and curated 1:1 meetings. Tomi Popoola, CEO of Slash Finances and Lord Holmes, Member of the UK House of Lords are the confirmed keynote speakers. Tomi will share insights on From Innovation to Operating Model: How AI, Cloud and Automation Are Transforming Corporate Lending for Real-World Impact, exploring how emerging technologies are reshaping lending models and driving tangible outcomes across the market. Lord Holmes will examine the role of emerging technology in the UK, reflect on current trends and the future outlook, and consider the evolving intersection between technology and the loan markets. Why it matters: Accelerate digital execution, reduce operational cost and risk, and align on standards that improve interoperability across the loan lifecy...

4 December 2025

Voltera | Enabling Multilayer Flexible PCBs with Direct Ink Writing Technology

Author: Jesus Zozaya, CEO, Voltera, sales@voltera.io

It was our pleasure to present a masterclass at TechBlick Berlin on advancements in printed electronics prototyping. As a follow-up, we’d like to share an example of a multilayer flexible circuit we printed on PET. To watch this presentation in full, please purchase TechBlick Annual Pass at https://www.techblick.com/registration and login to TechBlick platform https://app.swapcard.com/event/techblick

MATERIALS USED Voltera Conductor 3 silver ink ACI Materials FS0142 Semi-Sintering Conductive Ink ACI Materials SI3104 Stretchable Printed Insulator Voltera T4 solder paste Voltera solder wire Siraya Tech Tenacious Flexible Resin SUBSTRATES USED Normandy Coating polyethylene terephthalate (PET) FR1 board TOOLS AND ACCESSORIES V-One PCB printer NOVA materials dispensing system Voltera disposable nozzle Nordson EFD 7018395 dispensing tip Nordson EFD 7018424 dispensing tip Nordson general purpose dispense tips NE555DR timer LEDs Project Overview Purpose The goal of this project was to prototype a flexible multilayer LED wheel roulette circuit that was traditionally considered rigid and validate the redesign of the circuit. Design This project involves a multilayer flexible PCB for the LED roulette circuit and a traditional control board that powers it. We adapted the design of an LED roulette circuit, originally developed for a 3” × 4” FR4 board by ITIZ, Voltera’s authorized reseller in Korea. This new version is pri...