Blackleaf | Water-Based Graphene Inks: A Sustainable Innovation for Thermal Heating Elements

- Jan 6

- 7 min read

Authors:

Anaghim Nasri, R&D Engineer

Quentin Maerklen, Process Engineer

Water-based graphene inks are emerging as a groundbreaking solution for next-generation heating technology. By leveraging graphene’s exceptional thermal and electrical conductivity, these inks enable thin, flexible heating elements that deliver high heat output with minimal power. Importantly, sustainability is becoming a key market driver, with growing demand for water-based, responsibly sourced graphene inks as eco-friendly alternatives to metal-based conductive materials.

This article explores how water-based graphene inks provide efficient and uniform heating, their environmental advantages over conventional carbon-based inks, and the role of Blackleaf in driving this innovation forward. As the demand grows for eco-friendly heating (from automotive seats to building systems), water-based graphene inks offer a powerful combination of performance, sustainability, and scalability.

Introduction: Blackleaf Inks for Next-Generation Heating

One of the pioneers bringing this technology to market is Blackleaf, a French graphene manufacturer and ink developer. Blackleaf has positioned itself as a leading producer of graphene and formulated inks in Europe, with a capacity of over 120 tons per year of graphene products by 2027, all produced in-house in France.

Blackleaf’s product portfolio includes ready-to-use graphene conductive inks for a variety of uses. Notably, the company has focused on graphene-based heating inks as a core offering that can be applied in two complementary forms- as flexible heating films or direct heating coatings on surfaces. This allows integration into diverse scenarios.

We are exhibiting at the Future of Electronics RESHAPED.

The events will take place in Berlin on 21-22 October 2026.

Please register for the event, meet us in person and see our technology in action.

Key Properties of Graphene Inks

Graphene inks offer a unique combination of high conductivity, low-temperature processing, and compatibility with industrial printing. The key properties below illustrate why they outperform conventional carbon and metal-based formulations.

2.1. High Electrical Conductivity

Graphene’s high charge-carrier mobility enables low-resistance films at low solid content. While conventional carbon inks require >25–30% solids to reach 20–30 Ω/sq/mil, Blackleaf’s water-based formulations achieve 8–15 Ω/sq/mil with only 6–8% solids.This ensures:

Efficient Joule heating at low voltage.

Lower energy consumption.

Resistance tunability via mesh, deposition thickness, and curing profile.

2.2. Low-Temperature Processing

Graphene inks cure at <150 °C, reducing energy demand during manufacturing and enabling deposition on flexible polymer substrates. This contrasts with metal-based inks (e.g., silver nanoparticle systems requiring >250 °C sintering) and helps lower the overall carbon footprint of production.

2.3. Tunable Rheology & Broad Printability

Formulations can be engineered for multiple coating/printing processes, including screen printing, spray coating, and slot-die/bar coating.

Key rheological traits include:

Controlled thixotropy.

Stable viscosity under shear.

Excellent wetting on polymeric surfaces.

2.4. Strong Substrate Adhesion

Optimized binder–graphene interactions provide robust adhesion on a wide range of substrates, including PET, PU, PC, textiles, and paper (see Figure 1), ensuring mechanical stability under bending, heating cycles, and long-term use.

a The curing temperature depends on the target application and the substrate used. A minimum drying temperature of 90 °C is required to ensure proper film drying.

Table 1 compares the electrical performance of graphene inks processed by different coating and printing techniques, showing that sheet resistance strongly depends on deposition method and film thickness. Spray coating yields thicker films (~25 µm) with lower sheet resistance, while screen printing produces thinner layers (~12–15 µm) with higher resistance. All films were cured on treated PET at low temperatures (120–150 °C), confirming process compatibility. Overall, the results demonstrate that sheet resistance can be tuned by controlling deposition technology, thickness, and curing conditions to meet different heating performance requirements.

High Efficiency Heating with Graphene Inks

3.1 Use-Case Integration of Printed Graphene Heating Films

The experimental investigations reported in this work were carried out on flexible graphene-based heater patches specifically designed for high-efficiency surface heating. These ultra-thin devices can be integrated or bonded onto a wide variety of substrates wherever localized heat input is required.

As illustrated in Figure 2, heaters combine a graphene heating layer with copper electrodes on a polymer substrate, optionally laminated with a polymer topcoat, and are supplied with a pressure-sensitive adhesive to enable straightforward mounting. They are engineered to deliver surface power densities up to 6 W·cm⁻² with a maximum operating temperature of 250 °C, while maintaining excellent thermal uniformity thanks to the high in-plane conductivity of the graphene ink and the resulting direct thermal transfer to the heated surface.

As shown in Figure 3, patch geometry and overall dimensions are tailored to the application, and the devices remain highly flexible, with a bending radius down to 2 mm, making them suitable demonstrators for the high-efficiency heating performance of the graphene inks evaluated in the following sections.

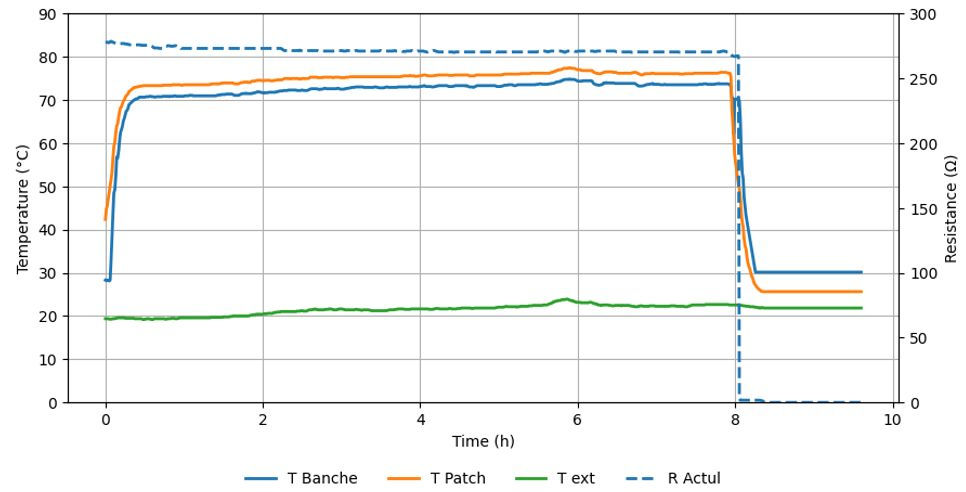

3.2. Thermal tests – Endurance (8 h at 75 °C)

To assess the stability of heaters manufactured with water-based graphene inks, a representative flexible patch was supplied with 160 W under a maximum voltage of 230 V for 8 h. Under these conditions, and with the mounting configuration described above, the device reached a steady-state temperature of 75 °C as displayed in Figure 4.

Figure 4 shows a slight increase in the equilibrium temperature throughout the experiment. This drift is distributed to variations in the ambient temperature, as the external temperature Text exhibited the same upward trend as the temperature measured on the heater surface.

The corresponding evolution of resistance is summarized in Table 2. Over the 8 hrs period, the resistance decreased by 11.5 Ω, i.e. about 4 %, with values ranging from 280.5 Ω to 269.0 Ω (mean 271.5 Ω, standard deviation 2.3 Ω). This behaviour is consistent with the negative temperature coefficient (NTC) of the graphene-based coating: the resistance decreases slightly as temperature increases, before reaching a stable value. No degradation, delamination or visible damage of the heater was detected after the endurance test, indicating that the integrity of the patch was preserved.

3.3 Thermal tests – Cycling (100 cycles from ambient to 75 °C)

Using the same experimental setup, a thermal cycling protocol was applied over 100 cycles between 40 °C and 75 °C, for a total duration of 27 h. To reach 75 °C more rapidly in each cycle, the input power was slightly increased to 180 W (Figure 5).

For clarity, Figure 6 presents only the first 10 cycles over a 3-hour window. During these initial cycles, a modest decrease in resistance of approximately 3 % was observed, after which the resistance stabilized and remained constant over the remaining 90 cycles. As in the endurance experiment, no macroscopic damage or change in appearance of the heater was observed at the end of the test, confirming that the patches withstand repeated thermal loading between 40 °C and 75 °C.

Potential application to low-temperature floor heating for energy retrofits

The combination of high-power density, mechanical flexibility, and stable operation demonstrated above suggests that heaters based on water-based graphene inks are suitable candidates for low-temperature radiant floor heating, particularly in the context of energy renovation. In such systems, flexible patches can be laminated or bonded onto intermediate substrates (e.g. underlays, boards, or prefabricated panels) and subsequently covered by conventional flooring materials such as laminates, engineered wood or ceramic tiles, provided that appropriate dielectric and mechanical protection layers are implemented (see Figure 7).

The tunability of sheet resistance and heater geometry enables precise control of power density while maintaining safe current and voltage levels. The observed negative temperature coefficient behavior may further contribute to safety by limiting local overheating. Combined with water-based inks and scalable printing processes, these heaters are well suited for large-area, flexible manufacturing, with future work focusing on durability, environmental resistance, and system-level integration for building-scale applications.

Further work should therefore address long-term mechanical fatigue under foot traffic, moisture and humidity resistance, dielectric withstand under building-standard test protocols, and system-level integration (insulation layers, floor build-up, control strategies) to fully validate these printed heaters as a viable technology for low-temperature, energy-efficient floor heating in renovation scenarios

Water-Based Formulation: Key Enabler for Sustainable Printed Heating Technologies

Water-based graphene inks represent a major shift in the development of next-generation printed heating solutions. Unlike traditional conductive inks that rely on organic solvents such as NMP, DMF, toluene, or glycol ethers, water-based formulations eliminate volatile organic compounds (VOCs) and significantly reduce toxicity during manufacturing and end-use. This not only improves operator safety but also simplifies processing, waste handling, and regulatory compliance.

Beyond their environmental benefits, water-based graphene inks provide significant operational and economic advantages at the manufacturing level. By eliminating organic solvents, they drastically reduce maintenance requirements on printing and coating equipment: no solvent residues, fewer nozzle or mesh obstructions, and faster cleaning cycles. Water replaces costly solvent-based cleaning agents, lowering consumable usage while minimizing operator exposure to hazardous chemicals. Additionally, the absence of aggressive solvents extends the lifetime of pumps, seals, tubing, screens and elastomer components, which are typically degraded by solvent-based formulations. Because water-based inks do not require solvent-extraction systems, safety infrastructure becomes simpler and less expensive.

Overall, water-based ink processing enables lower operational expenditure (OPEX), higher equipment uptime, greater throughput stability, and reduced production complexity, which is particularly advantageous for large-scale deployment of printed heating technologies.

Conclusion

Water-based graphene inks represent a key enabling technology for next-generation heating elements, combining high electrical performance with low environmental impact. Continued improvements in graphene exfoliation, formulation, and printing compatibility are expected to further expand their functionality toward smart, energy-efficient heating systems. In this context, Blackleaf plays a central role by delivering industrially scalable, sustainably produced graphene inks capable of addressing both performance and regulatory requirements. By bridging advanced materials science with real-world manufacturing constraints, graphene-based heating films are positioned to transition from emerging solutions to widely adopted technologies across sectors aerospace (leading-edge anti-icing systems), electric vehicles (interior comfort heating) and building applications (radiant heating panels).

Join the flagship TechBlick event in California on 10-11 June 2026, and in Berlin on 21-22 October 2026

This event is the global home of the Additive, Printed, Sustainable, Hybrid and 3D Electronics. It is where the global industry connects, where the latest is unveiled and where big products, novel ideas and key projects and partnerships are discussed and forged. This event is not to be missed!

This year, the events will also feature

the Future of Wearables Reshaped (in California) and Perovskite Connect (in Berlin).

Comments