Introducing the Program - Additive, Hybrid and 3D Electronics - Why Should You Join TechBlick's The Future of Electronics RESHAPED?

- Aug 19, 2025

- 4 min read

Updated: Aug 22, 2025

The flagship Future of Electronics RESHAPED conference and exhibition (22 & 23 OCT 2025, Berlin) is set to be the most important event of the year focused on additive, hybrid, 3D, sustainable, wearable, soft and textile electronics.

This year the program features a world-class agenda with over over 100 superb invited talks from around the world, 12 industry- or expert-led masterclasses, 4 tours, and over 90 onsite exhibitors.

In this article, we discuss and highlight various innovative talks at the event around the theme of Additive, Hybrid and 3D Electronics. In future articles, we will cover further technologies including smart surfaces, sustainable electronics, printed medical electronics, novel materials and beyond.

Explore the full agenda now and join the global industry in Berlin on 22 & 23 OCT 2025.

Let us RESHAPE the Future of Electronics together, making it Additive, Hybrid, 3D, R2R, Soft, Flexible, Wearable, Textile and Sustainable.

Register before 12 Sept 2025 for the best rates

Lockheed Martin (USA)– Paul Gaylo explores the transition of flexible hybrid electronics (FHE) from lab to field applications. Case studies on copper printing and flexible RF circuits illustrate how FHE can deliver SWaP-C advantages in defense systems while meeting reliability demands. The talk emphasizes concurrent engineering and early integration of design with advanced manufacturing to overcome barriers to FHE adoption.

Fuji Corporation (Japan) – Ryojiro Tominaga demonstrates additively manufactured multilayer circuits with embedded components. By combining silver nano-ink inkjet printing, UV-curable resin molding, and ultra-low temperature surface mount, they fabricate stacked, three-dimensional devices. This approach enables new device geometries and points toward a paradigm shift in electronics manufacturing.

National Research Council Canada (Canada) – Chantal Paquet introduces Volumetric Additive Manufacturing (VAM) for 3D electronics. Using tomographic projection, VAM prints entire objects in seconds and enables “overprinting” of functional polymers onto existing structures. Subsequent metallization produces high-resolution 3D conductors. The talk will cover resin development, printing challenges, and the technology path toward scalable 3D electronic fabrication. Explore full Agenda and Register before 12 Sept 2025 for the best rates

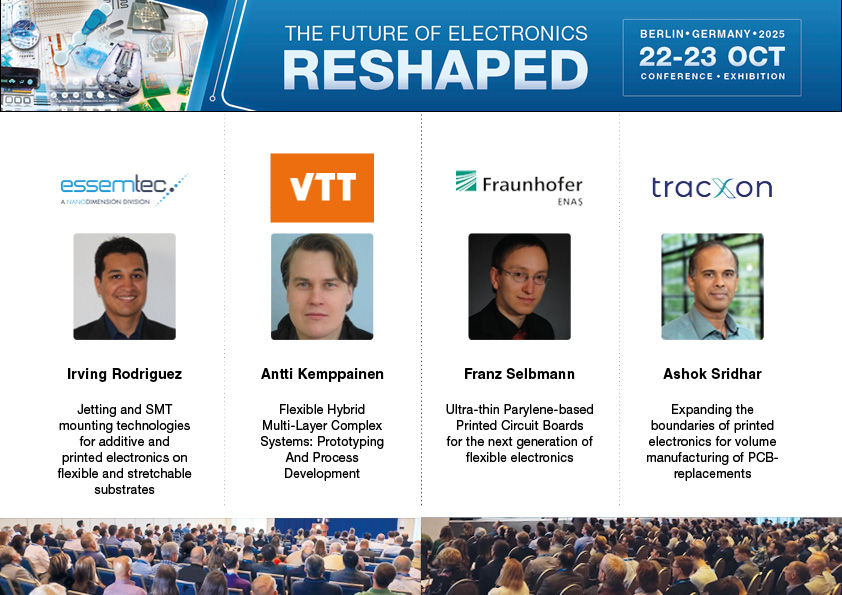

Fraunhofer ENAS (Germany) – Franz Selbmann showcases ultra-thin Parylene-based PCBs with thicknesses down to 20 µm. Combining Parylene as substrate, dielectric, and encapsulant, these flexible boards integrate redistribution layers, vias, and multiple metal stacks via microsystem and printing techniques. Demonstrated with gold, copper, and aluminum, the resulting PCBs deliver excellent electrical performance under bending and enable direct integration of sensors and components for IoT and wearable electronics.

Essemtec (Switzerland)– Irving Rodriguez explores jetting and SMT mounting technologies for flexible and stretchable electronics. Advanced all-in-one platforms combine multi-valve jetting of conductive inks, adhesives, and liquid metals with adaptive pick-and-place. Features such as laser height mapping and real-time process control support precision assembly on soft substrates, opening scalable routes to wearable, medical, and soft robotics electronics.

TracXon (Netherlands)– Ashok Sridhar presents a patented high-speed roll-to-roll process for vertical interconnects (VIAs), a key bottleneck in printed electronics. The new VIA filling system, compatible with both R2R and S2S lines, enables true double-sided and high-density circuitry. By eliminating costly multilayer isolation stacks, this breakthrough moves printed electronics closer to PCB-level complexity and scalable volume manufacturing.

VTT (Finland) – Antti Kemppainen discusses prototyping and process development of flexible hybrid multilayer systems for medical electronics. The talk covers multilayer sensor designs, dense integration, and elastic/wearable devices, addressing the need for both performance and manufacturability. This talk highlights pathways from concept design through prototyping to upscaling for rapid deployment of advanced medical-grade hybrid electronics.

AMAREA Technology (Germany) – Robert Johne introduces ceramic-based printed electronics via multi-material additive manufacturing. By integrating conductors and resistors directly into ceramic components, AMAREA achieves miniaturized, functional devices without assembly. Applications include embedded electrical circuits in glass-ceramics, metal-ceramic hybrids, and complex multifunctional components. The presentation covers material qualification, process optimization, and practical demonstrations of ceramic-embedded electronics.

Lithoz (Austria) – Christoph Hofstetter highlights additive manufacturing of dielectric ceramics and ceramic-metal systems using lithography-based ceramic manufacturing (LCM). A dual-vat system enables clean switching between materials, producing dielectric ceramics with permittivity 3–60 and successful co-sintering of ceramics with silver or copper. The results demonstrate LCM’s potential for functional ceramic components with tailored electrical properties, advancing multi-material ceramic electronics.

Q5D Technologies (United Kingdom) - Ben Monteith presents advances in 5-axis laser-assisted selective metallization for large 3D parts. By combining robotic motion control with laser activation and conductive material deposition, they enable direct integration of wiring and interconnects onto complex geometries. This approach eliminates separate harnesses, reduces weight, and supports high-performance substrates such as polymers, glass, and ceramics—advancing scalable 3D electronic integration.

XTPL presents additive manufacturing for next-generation microelectronics, focusing on micron-scale precision printing with conductive and dielectric nanomaterials. Using silver, copper, and gold pastes, they demonstrate microdispensing for semiconductor packaging, displays, and sensors, enabling miniaturization, flexible design, and cost-efficient production. The talk reviews state-of-the-art methods, highlights yield and repeatability challenges, and outlines practical solutions for scaling microfabrication into industrial production.

Printed Electronics Limited (PEL) (United Kingdom) introduces drop-on-demand deposition of highly viscous functional inks, traditionally confined only to screen printing. Leveraging piezovalve viscous-jet technology, they enable digital deposition of inks far above inkjet viscosity limits (>5,000 cP). Demonstrations include single-pass, high-performance digital printing of heavily loaded conductive materials for next-generation printed electronics.

ImageXpert (USA) – Jochen Christiaens presents a structured methodology for inkjet printhead selection in advanced printed electronics. The session covers drop volume, nozzle density, waveform tuning, and material compatibility, comparing leading piezoelectric printheads. Case studies highlight performance trade-offs with challenging inks and substrates, giving attendees a practical framework for selecting printheads across R&D and production.

Comments