Revolutionizing High-Volume Production: The Intlvac Icarus Indium Solder Bump Deposition System

- Aug 19, 2025

- 4 min read

Updated: Aug 29, 2025

In the fast-paced world of advanced manufacturing, precision, speed, and reliability are non-negotiable. Enter the Intlvac Icarus Indium Solder Bump Deposition System—a game-changing solution designed to meet the rigorous demands of high-volume production. With over 30 years of expertise in system manufacturing and coating services, Intlvac has engineered a system that delivers exceptional performance, minimal maintenance, and rapid turnaround times.

A solder bump is a small, raised deposit of indium solder that is typically applied to the surface of a microelectronic device. Solder bumps are commonly used in semiconductor packaging and flip-chip bonding processes, microprocessors, integrated circuits, and other electronic components. They provide an efficient and reliable method for connecting chips to substrates, allowing for high-performance and compact devices.

Why Indium Bumps?

Indium bumps are essential for advanced applications due to their unique properties. They enable higher packing density and increased device speeds, making them ideal for flip-chip bonding in pixel readout applications. Additionally, indium offers strong mechanical properties and superconductivity at temperatures below 3.4K, ensuring reliable performance in demanding environments. Its role as an under-bump diffusion barrier further enhances device performance by preventing material intermixing and maintaining structural integrity.

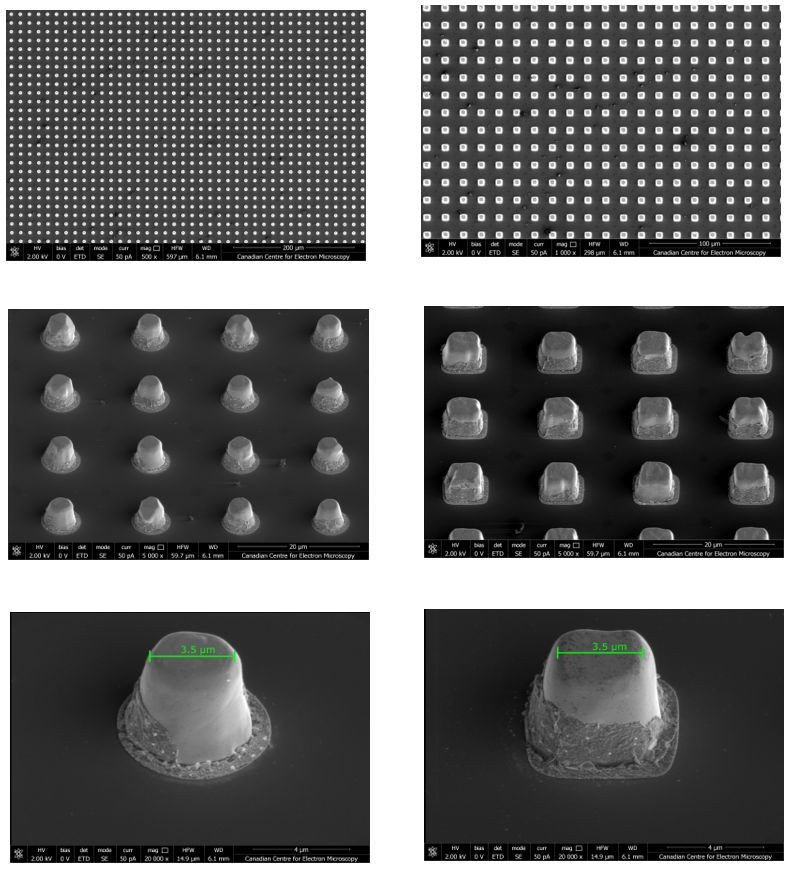

High-Throughput Production with Unmatched Precision

The Icarus system is optimized for efficiency, completing 200 mm diameter wafers in under 90 minutes. Its proprietary technology ensures precise control over film thickness, supporting bump heights ranging from 1 to 40 microns. This makes it ideal for applications in microelectronics, microLEDs, flip-chip bonding, and optoelectronics—industries where precision is paramount.

The system’s capacity for hundreds of depositions without opening the main chamber significantly reduces downtime. When indium refills are required, the process is streamlined, taking only minutes to exchange the empty crucible with a pre-charged one.

Tackling Dendritic Growth for Superior Performance

One of the standout features of the Icarus system is its ability to suppress dendritic growth, a common challenge in indium deposition. Dendritic growth, characterized by uneven spikes that compromise mechanical and electrical performance, is effectively controlled through elevated deposition rates and low deposition temperatures. The result? High-quality indium films with:

Spit-free deposition up to 70 Å/s

<5% uniformity variation across 200 mm wafers

Advanced thermal bonding for precise temperature control (+60°C to -75°C)

Superior lift-off yields and consistent bump arrays

Optimized for Uniformity and Fill

Achieving uniform coating and optimal hole filling is no small feat, but the Icarus system excels here too. By aligning deposition flux perpendicularly to the substrate, it prevents hole closure and ensures consistent results across both square and round bump arrays. This precision allows for up to 200 depositions of 2μm films without requiring access to the main chamber.

Ultra-High Purity Indium for Next-Level Applications

Intlvac takes purity seriously. Starting with 5N (99.999%) grade indium, the company performs additional purification steps under vacuum to eliminate residual impurities. The result is an oxide-free, ultra-pure indium film that meets the stringent demands of industries like quantum computing, optoelectronics, and microelectronics.

Indium’s unique properties, such as its low melting point (156.6°C), high thermal conductivity, and compatibility with complex crystal structures, make it an ideal material for forming reliable electrical contacts in semiconductor devices. Its ductility and thermal stability further enhance its suitability for applications requiring efficient heat dissipation and low processing temperatures.

Advanced Features for Seamless Operation

The Icarus system is packed with features that enhance its performance and usability:

Automatic Load-Lock: Transfers and pre-conditions wafers up to 200 mm, removing contaminants and water vapor without physical etching.

Cryogenic Temperature Control: Films are grown at temperatures as low as -90°C, enhancing shear strength and adhesion while preventing lateral atom migration.

Dry Substrate Bonding: A Drichuck pad ensures efficient heat transfer and substrate cooling, maintaining optimal wafer temperatures for superior deposition quality.

Physical Vapor Deposition (PVD): Compared to electroplating, PVD offers superior adhesion, uniformity, and density, with precise control over coating thickness and minimal environmental impact on film properties.

Redefining High-Volume Bump Fabrication

With its combination of ultra-high-purity indium, precise thermal control, and industry-leading uniformity, the Icarus system sets a new standard in high-volume bump fabrication. Whether you're manufacturing microLEDs, optoelectronics, or quantum devices, this system delivers consistent, repeatable performance with minimal maintenance and rapid turnaround times.

In a world where production schedules are tighter than ever, the Intlvac Icarus Indium Solder Bump Deposition System empowers manufacturers to stay ahead—without compromising on quality or reliability.

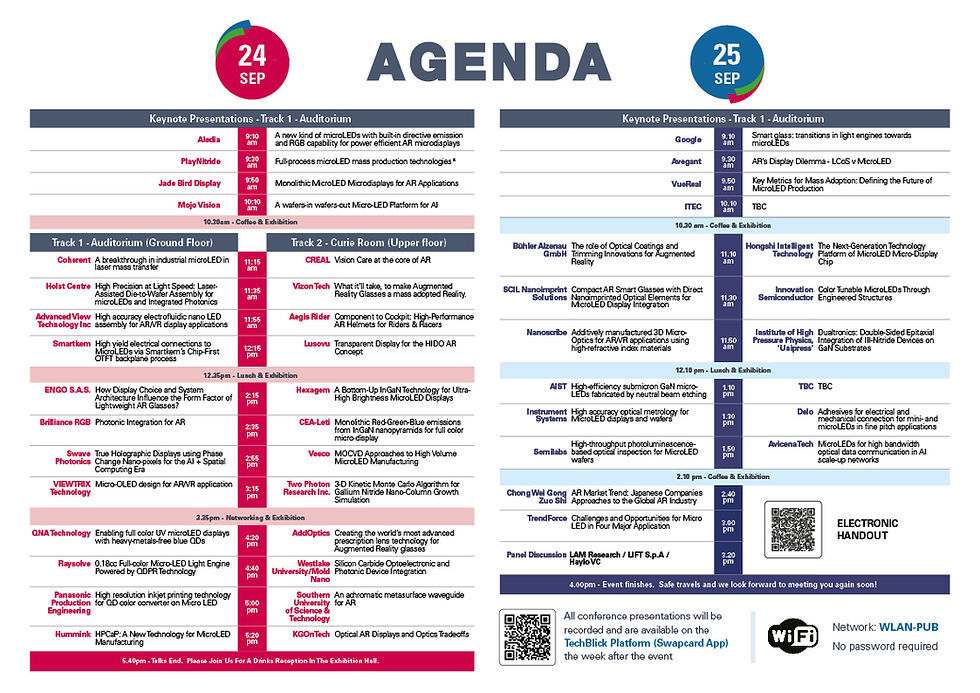

What to expect at the MicroLED Connect & AR/VR Connect event in Eindhoven on 24-25 September 2025?

Comments