Introducing the Program - Roll-to-roll electronic and photovoltaic manufacturing

- Sep 17, 2025

- 4 min read

Why Should You Join TechBlick's The Future of Electronics RESHAPED?

The Future of Electronics RESHAPED conference and exhibition (22 & 23 OCT 2025, Berlin) is set to be the most important event of the year focused on additive, hybrid, 3D, sustainable, wearable, soft and textile electronics.

This year the program features a world-class agenda with over 100 superb invited talks from around the world, 12 industry- or expert-led masterclasses, 4 tours, and over 95 onsite exhibitors.

In this article, we discuss and highlight various innovative talks at the event around the theme of R2R and reel-to-reel manufacturing of electronics and photovoltaics. In future articles, we will cover further technologies including smart surfaces, sustainable electronics, printed medical electronics, novel materials and beyond.

Explore the full agenda now and join the global industry in Berlin on 22 & 23 OCT 2025. Let us RESHAPE the Future of Electronics together, making it Additive, Hybrid, 3D, R2R, Soft, Flexible, Wearable, Textile and Sustainable.

Explore the Full Agenda and Register before 10 October 2025 for the best rates

Wiliot – Eylon Gersten presents scaling ambient IoT with battery-free Bluetooth tags. Produced via reel-to-reel manufacturing, these ultra-low-cost inlays integrate printed sensors for temperature, humidity, light, and proximity. The talk highlights Wiliot’s novel communication method and the role of printed electronics in enabling sustainable, large-scale deployment of billions of connected devices.

Fraunhofer EMFT – Alaa Abdellah presents endless electronics via roll-to-roll digital lithography. A direct-write UV system combined with semi-additive processing enables ultra-long, high-resolution metal patterns with seamless digital stitching. Applications include tamper-protection foils, superconducting interconnects, and high-density flexible cables, with integration of packaged or bare dies through advanced bonding for scalable continuous electronics manufacturing.

SALD B.V. – Hindrik de Vries presents a paradigm shift in roll-to-roll spatial atomic layer deposition (s-ALD) for perovskite solar cells. Operating at atmospheric pressure with parallel precursor exposure, the new R2R s-ALD tool achieves deposition speeds 100× faster than conventional ALD while maintaining high film quality. Applications include passivation, charge transport, and moisture barrier layers critical for efficient, stable PSCs.

👉 Intellivation LLC – Josephson Liz presents a flexible roll-to-roll sputtering platform delivering lightweight barrier and transparent conductor coatings for perovskite solar cells. By combining PET substrates with sputtered thin films, the technology enhances environmental stability, optical transmission, and current collection, addressing key challenges of scalability and durability in flexible PSC manufacturing.

👉 Eastman Kodak – Carolyn Ellinger highlights how roll-to-roll flexography can complement and surpass screen printing for high-resolution, high-volume printed electronics. The talk outlines benefits and challenges of scaling flexo, with lab-to-production data showing its potential for cost-effective, precise circuit replication.

Explore the Full Agenda and Register before 10 October 2025 for the best rates

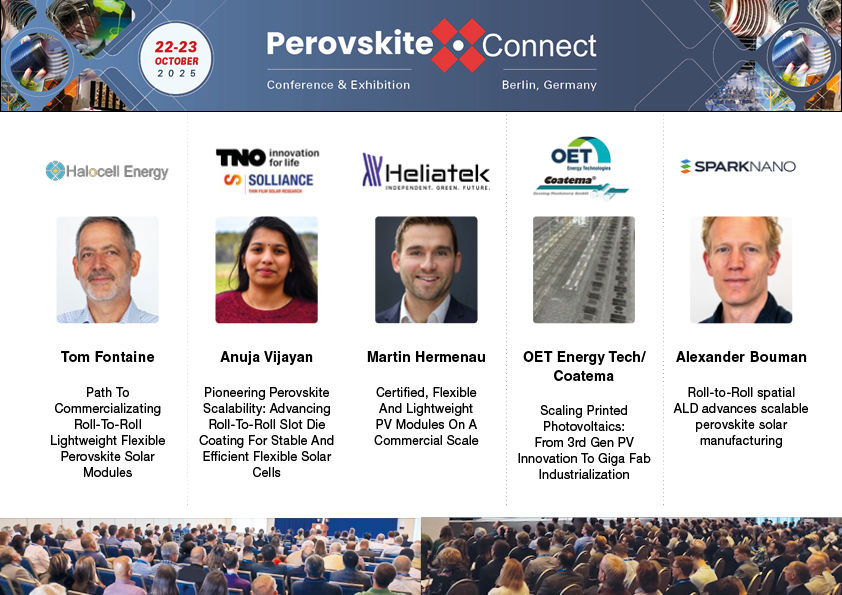

Halocell Energy – Tom Fontaine presents the commercialization path for roll-to-roll flexible perovskite solar modules. A scalable printing process enables lightweight modules with high power density and extended lifetimes under low-light conditions, particularly suited for IoT and autonomous applications. The talk addresses key challenges in scaling deposition techniques and minimizing material waste.

TNO | Solliance – Anuja Vijayan discusses advancing roll-to-roll slot die coating for scalable perovskite solar cells. Using green solvents and ambient processing, R2R-coated flexible substrates achieved efficiencies of up to 13%, with sheet-to-sheet devices on metal foils exceeding 15% and maintaining stability over 3000 hours. The work highlights process optimization, reproducibility, and modular mass-customization approaches for commercial viability.

Heliatek – Martin Hermenau presents certified lightweight flexible PV modules at commercial scale. Heliatek introduces the first IEC 61215-certified OPV module and explores incorporating perovskite stacks into existing R2R pilot lines. Drawing on expertise in organic multilayer vacuum deposition and encapsulation, the talk highlights pathways and challenges for large-scale flexible perovskite-based PV production.

OET Energy Technologies / Coatema present scaling printed photovoltaics from 3rd-gen innovation to Giga Fab industrialization. Through the Flex2Energy initiative, the first Giga Fab for printed PVs integrates roll-to-roll printing, automated assembly, in-line metrology, and AI-driven analytics. The talk highlights scalable OPV solutions for building-, vehicle-, and agriculture-integrated photovoltaics, enabling lightweight, flexible, and sustainable solar modules to support the global clean energy transition.

SparkNano – Alexander Bouman presents roll-to-roll spatial ALD for scalable perovskite solar manufacturing. By separating precursor exposures, the Omega system achieves >100× higher deposition rates than conventional ALD, supporting web speeds up to 80 m/min and widths of 1.5 m. Demonstrated for SnO₂ electron transport layers, the approach enables uniform, high-quality films at 50–150 °C, advancing PSCs from lab-scale to gigawatt-scale production.

Explore the Full Agenda and Register before 10 October 2025 for the best rates

SATO Global – Stefan Linz presents how RFID-driven digital twins enable real-time manufacturing intelligence, integrating with SAP and 3D visualization to boost efficiency and predictive maintenance. Looking ahead, sensor-enabled RFID tags promise richer data capture and sustainability gains, reshaping Industry 4.0 beyond tracking toward smarter, adaptive operations.

TracXon – Ashok Sridhar presents a patented high-speed, roll-to-roll (R2R) compatible process for vertical interconnect access (VIA) fabrication, addressing one of the biggest bottlenecks in printed electronics. By enabling robust, double-sided, and high-density circuitry, TracXon’s approach positions printed electronics as a sustainable and scalable alternative to traditional subtractive PCBs, unlocking new opportunities for IoT, wearables, smart buildings, and structural health monitoring.

Sunray Scientific – John Yundt presents UV-cured anisotropic conductive epoxy (ZTACH® ACE) for electronic assemblies. This pressure-less interconnect cures in seconds under UV light, avoiding thermal damage to sensitive components and substrates. Using ferromagnetic particle alignment, it enables fine-pitch, low-resistivity vertical connections while providing underfill in a single step. The approach supports scalable, high-throughput SMT and roll-to-roll manufacturing for miniaturized, low-cost electronics.

Explore the Full Agenda and Register before 10 October 2025 for the best rates

Comments