LevSurf™: A Technical Evolution in 3D-Formable Hard-Coated Films

- khashayar Ghaffarzadeh

- Oct 17, 2025

- 2 min read

LevSurf™ is a UV‑cured hard-coated polycarbonate (PC) film engineered to enable three-dimensional forming for IMD/FIM manufacturing — combining scratch resistance and robust chemical durability with material flexibility.

The coating is fully cured prior to forming, eliminating the need for post-processing steps like secondary UV curing or lacquer, increasing throughput and reducing defect rates.

Tailored for cover-lens substitution in high-resolution displays (e.g. automotive instrument panels), LevSurf offers optical clarity comparable to glass, with weight savings and potential reductions in CO₂ footprint per vehicle lifecycle.

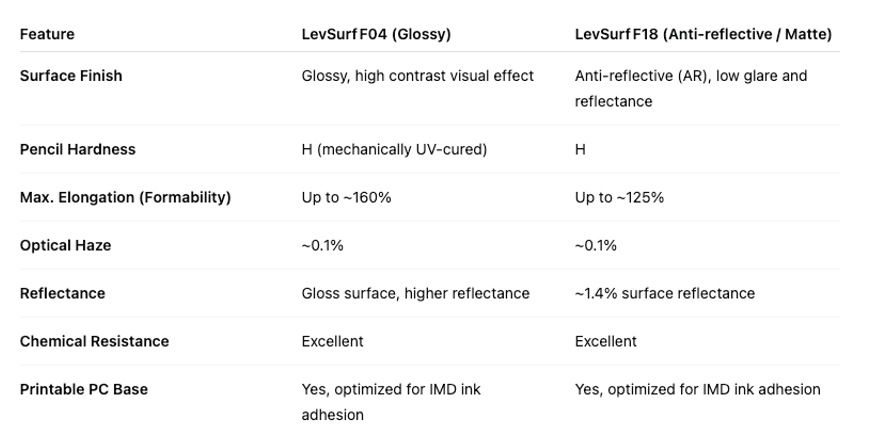

Constructed using polycarbonate substrate, LevSurf features anti-reflective (F18) or glossy (F04) finishes, each optimized for display readability or aesthetic effect.

The hardcoat layer yields durability — pencil hardness H and full chemical resistance while allowing elongation of up to ~125% during forming without cracking.

The film maintains excellent optical performance, with haze as low as ~0.1% and reflectance around 1.4%, paired with anti-fingerprint and anti-glare finishes for improved visual performance.

Kimoto applies the UV-curable coating using ISO‑certified clean‑room R2R coating lines, ensuring minimal particulate contamination for high-resolution display optics.

After coating, the film can be printed (e.g. for in-mold graphics), then formed via IMD/FIM tooling. As the coating is fully cured, there’s no post-curing required — meaning lower cycle times and higher yield.

LevSurf supports seamless design integration into flowing, curved cockpit surfaces, enabling both functional displays and aesthetic continuity in automotive interiors.

Performance Metrics & Technical Benefits

Hardness: Pencil hardness up to H, delivering abrasion resistance typically reserved for glass surfaces.

Flexibility: Supports elongation up to ~125% during forming operations without delamination or cracking.

Optics: Very low haze (~0.1%) and reflectance (~1.4%) in anti-reflective variants; glossy versions deliver high contrast and gloss perception.

Durability: UV-cured surface resists chemicals and repeated human interaction without requiring protective overcoats.

Applications & Impact

Automotive HMI: LevSurf films are popular for dashboards, infotainment panels, and other high-touch surfaces where curvature and display transparency are essential.

Lightweight display integration: By replacing traditional glass cover lenses, LevSurf reduces weight and contributes to lower production costs and CO₂ emissions.

Large-panel design freedom: Ideal for OEMs and Tier‑1 integrators looking to embed seamless visual continuity across interior trims with multiple display zones.

LevSurf™ represents a compelling fusion of precision materials engineering, high-performance optical coating, and process-compatible flexibility. Its ability to replace fragile glass with lightweight, durable polycarbonate, all while maintaining color fidelity and touch performance, positions it as a disruptive solution for next-gen HMI and display systems in automotive and consumer electronics.

Innovation in material design always fascinates engineers and hobbyists alike. These new coatings push the limits of flexibility and durability, sparking conversations far beyond manufacturing. Many compare it to how performance parts evolve in automotive tech. Browsing experiences on https://msd-ignition.pissedconsumer.com/review.html mirrors that same obsession with precision. Whether it’s a car engine or film substrate, enthusiasts love tinkering, optimizing, and debating performance outcomes. Technology may change rapidly, but passion for improvement stays the same across every field.