Scalable Metal Oxide Nano Inks for High-Performance Organic, Perovskite, and Thin Film Photovoltaics and OLEDs

- khashayar Ghaffarzadeh

- Aug 29, 2025

- 4 min read

Updated: Sep 1, 2025

#PerovskiteSolarCells #OLED #OrganicPV #PrintedElectronics #NanoInks #ElectronTransportLayer #FlexibleElectronics #Optoelectronics #RollToRoll #SmartMaterials #EnergyTech #SolarInnovation #DisplayTechnology #NextGenMaterials #SustainableElectronics

Author: Maryam Bari & Ashwani Jain PINA CREATION

Unlocking printable, low-temperature charge transport layers for next-generation optoelectronics

As next-generation optoelectronic technologies—such as Perovskite solar cells (PSCs), OLED displays, and Organic photovoltaics (OPVs)—move from lab to large-scale manufacturing, the pressure is on to find materials that are not only high-performing, but scalable, stable, and compatible with printed device architectures.

A critical bottleneck remains the Electron Transport Layer (ETL) and Hole Transport Layer (HTL). For technologies relying on delicate or flexible substrates, traditional materials such as Organic Semiconductors and traditional metal oxide inks pose serious limitations. High-temperature processing, moisture sensitivity, high cost, and limited lifetime all threaten the viability of commercial deployment.

At PINA Creation, we’ve developed a line of ready-to-use SnO₂, NiO and ZnO nano inks that overcome these barriers and unlock practical, large-area fabrication for flexible and rigid optoelectronics.

The ETL & HTL Processability

The ETL & HTL are responsible for:

Extracting electrons (ETL) and hole (HTL) from the photoactive layer

Blocking either holes or electrons to prevent recombination

Providing a stable interface with the electrode

Traditionally, organic semiconductors such as PCBM or PEDOT:PSS has been used in organic and perovskite devices due to its low-temperature processability, but it comes with drawbacks:

Short device lifetime due to degradation

Expensive material cost

Dependency on toxic organic solvents

Incompatibility with scalable coating methods

Traditional metal oxide inks such as TiO₂, while effective, requires >400°C annealing, eliminating its use in flexible substrates like PET or PEN.

Another example of the traditional materials is the solution-processed SnO₂ inks (typically from sol-gel precursors like SnCl₂) often demand complex multi-step processing, low performance, and still show limited uniformity and reproducibility when printed at scale.

PINA’s Nano Ink Advantage

To address these limitations, PINA has developed stable, printable dispersions of metal oxide nanoparticles, engineered specifically for printed electronics and scalable photovoltaic manufacturing.

PINA SnO₂, ZnO, and NiO nano inks are:

Ready-to-use ETL & HTL materials — no precursor conversion needed

Alcohol-based or water-based, non-toxic formulations

Solar Cell Efficiency Improvement: +20% increase in efficiency compared to current ETLs, as reported by PINA customers.

Compatible with perovskites, PEDOT:PSS, P3HT, and common OLED stacks

Cost-effective – up to 50% less than current alternatives

Low-temperature processed (<150°C) – enabling compatibility with plastic substrates, - lower energy consumption, and reduced manufacturing costs

Example: Cutting annealing from 450°C to 150°C reduces energy use by ~70%, saving $0.02–$0.05 per watt of solar panel manufacturing cost.

Shelf-stable – with 12+ months of shelf life, eliminating waste and supply disruptions

Eco-friendly – made with water and alcohol, improving safety and reducing compliance costs

Equipment-compatible – works with existing coating and printing lines

Impact:

Replacing current ETL/HTL materials with PINA’s inks can reduce material and processing costs by up to 30% per watt. For example: For a high-growth flexible solar manufacturer with ~$200M in annual production, this translates to $40–60M in recovered margin per year—a major competitive advantage.

In addition to water-based formulations, PINA recently launched alcohol-based SnO₂ nano inks represent a critical advancement for manufacturers working with moisture-sensitive materials such as perovskites or PEDOT:PSS. Traditional water-based inks often introduce interfacial degradation or layer instability, particularly in multi-layer printed devices. Alcohol-based inks, on the other hand, offer lower surface tension, faster drying, and greater compatibility with hydrophobic or organic layers, enabling defect-free film formation on flexible substrates. This makes them especially valuable in roll-to-roll printing environments, where consistent wetting and drying behavior is essential for yield and throughput.

Beyond SnO₂, ZnO, and NiO, PINA is expanding its material platform to include TiO₂ and ITO nano inks as transparent conductive layers — both tailored for low-temperature, printable electronics. These upcoming materials are being engineered with the same core principles: stability, scalability, and compatibility with next-generation device architectures.

Technical Highlights

Durability: PINA’s SnO₂ and ZnO films have passed IEC standard environmental stress tests:(85°C / 85% RH for 1000 hours) with no performance degradation

Energy Alignment: Suitable for both n-i-p and inverted p-i-n architectures

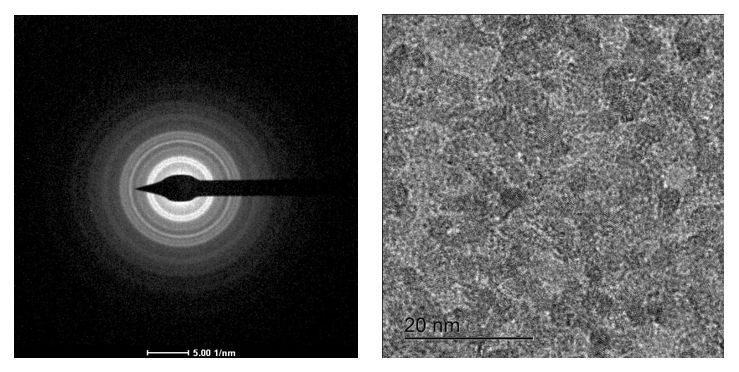

Film Uniformity: Smooth, dense coatings reduce recombination losses, small surface roughness <5nm

Mobility & Conductivity: Enables faster charge extraction and higher efficiency

ZnO Film coated by Slot-Die Coater

Use Cases Across Devices

Solar Cells

Stable ETL and HTL for Perovskite Solar Cells stack

Stable ETL and HTL for Indoor & Outdoor Organic Photovoltaics (OPV) modules for IoT & smart sensors

OLEDs

Printable ETL and HTL layers for flexible and transparent display structures

Compatible with hybrid organic-inorganic architectures

Printed Sensors & Thin-Film Transistors (TFTs)

High uniformity ETL or active layers for large-area printable electronics

From Lab to Pilot to Production

What sets PINA’s nano ink technology apart is its scalability. We design every formulation with the production line in mind — from the rheology and viscosity suited for precision coating, to the ink stability required for batch manufacturing, to the form factor flexibility needed for integration into existing platforms.

Conclusion

As Perovskite and OLED technologies edge closer to commercial viability, the materials used in their architecture must evolve. Tin Oxide, Zinc Oxide, and NiO Nano Inks represent a critical enabler — offering stability, scalability, and performance in one printable package.

Whether you're building the next high-efficiency solar module or pioneering flexible OLED displays, PINA’s Nano Ink platform is ready to support your roadmap.

For datasheets, compatibility trials, or free samples, visit: www.pinacreation.com or email us at info@pinacreation.com

We are Exhibiting in Berlin.

Visit our booth at the TechBlick Perovskite Connect event co-located with the Future of Electronics RESHAPED on 22-23 October 2025 in Berlin.

Contact us for your special discount coupon to attend

Download Conference Handout

Le marché des sous-vêtements masculins offre aujourd’hui une variété de coupes pensées pour répondre aux attentes diverses. Le Mini Slip homme se distingue par une taille plus basse qui lui donne un aspect discret et fonctionnel. Ce type de modèle est particulièrement apprécié par ceux qui portent des pantalons ajustés, car il assure une silhouette nette sans gêner les mouvements. C’est une option pratique pour combiner style et confort, en offrant une alternative moderne aux slips classiques ou aux boxers.