4 March 2026

13 Tech Breakthroughs: A Preview of TechBlick’s Electronics RESHAPED Silicon Valley

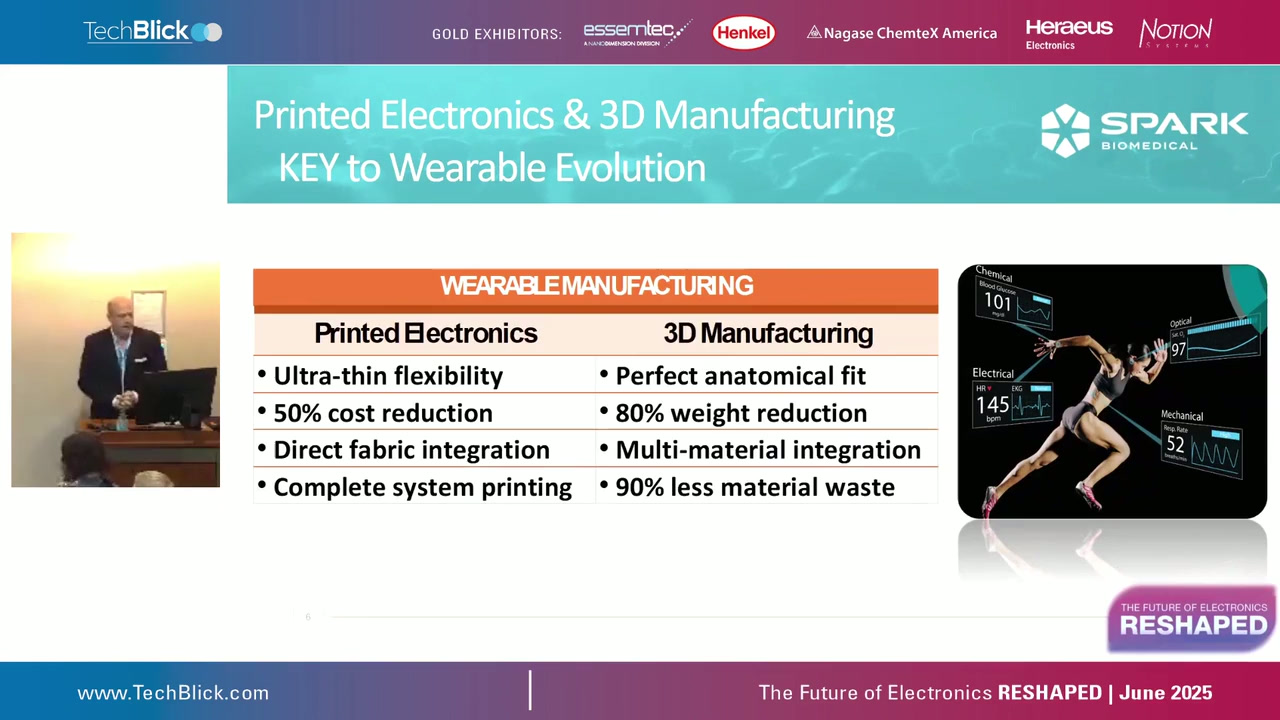

In this newsletter you will find short highlights given at various editions of TechBlick's Future of Electronics RESHAPED conference and exhibitions. In particular you can learn about the following: Join us in Mountain View, Silicon Valley, in June at the latest edition of the Future of Electronics RESHARED event. This is the most important event of the year dedicated to Additive, Printed, Hybrid and Sustainable Electronic. Explore Agenda here https://www.techblick.com/electronicsreshapedusa Frederic Güth | Fraunhofer ENAS: How does the substitution of the structural unit in Parylene polymers affect their properties and application-specific fine-tuning? Ryojiro Tominaga | Fuji Corporation: How does the low-temperature sintering process impact the choice of conductive inks and substrate materials? Ryan Banfield | Heraeus Electronics: Why is a solderable polymer necessary when high-temperature fired materials have been available for decades? Paul Gaylo | Lockheed Martin: How does the miniaturization of electronic warfare systems impact mission capabilities? Alejandro Covalin | Spark Biomedical: How can 3D printing and printed electronics overcome the limitations of traditional manufacturing in wearable devices? Eric Wolf | Essemtec: How does Essemtec manage the complexities of dispensing non-Newtonian fluids with varying rheological properties? Allan Neville | Human Systems Integration, Inc.: How does the manufacturing process for integrating electronics into garments differ fr...

24 February 2026

What Is Droplet Dispensing?

Mention droplet dispensing and you may immediately think of lab-on-a-chip (LoC) devices. Indeed, LoC devices rely on droplet dispensing systems or pipettes to distribute liquids for disease diagnostics. However, the application of droplet dispensing extends beyond life sciences. It finds various applications in consumer electronics (home inkjet printers), optics (lens arrays for fiber optics), life sciences (LoC systems, medical inhalers) as well as electronics manufacturing (dispensing solder droplets for flip chip bonding — attaching semiconductor chips to a substrate by flipping them onto tiny solder bumps) [1]. How does droplet dispensing work? Dispensing droplets manually involves using a syringe or micropipette to release individual droplets, and is common in laboratories for liquid handling. Micropipettes are engineered to deliver highly reproducible volumes and can reduce human variability, but achieving this precision requires proper technique and therefore subject to inter‑individual imprecision [2]. Automated droplet dispensing systems, in contrast, offer superior reliability by accurately jetting (drop-on-demand jetting systems ) or extruding ( direct ink writing systems) single discrete volumes of materials from a nozzle to a precise location. The target volume of each drop can range widely, from picoliters in microelectronics to microliters in lab applications. Achieving consistent volume is crucial in droplet dispensing for accuracy and reproducibility [3]. Dr...

20 January 2026

Future of Electronics RESHAPED USA

When: 10 & 11 June 2026 Where: Computer History Museum, Mountain View, California https://www.techblick.com/electronicsreshapedusa Join us and 600+ others from around the world next June at the heart of the Silicon Valley to RESHAPE the Future of Electronics together, one layer at a time, making it Additive, Printed, Sustainable, Flexible, Hybrid, Stretchable, Wearable, Textile, Structural, 3D... This event stands as the largest show in the USA dedicated specifically to Additive, Printed, Hybrid and 3D Electronics. It unites the entire global community—connecting end-users and manufacturers with equipment providers, material developers, and applied researchers. The 2026 edition is expected to welcome more than 600 attendees and 80 exhibitors , supported by three parallel conference tracks , alongside masterclasses and technical tours designed to bridge innovation with real-world deployment. A major highlight for 2026 is the partnership with NextFlex , the US-based consortium at the centre of the Printed and Hybrid Electronics ecosystem. The inclusion of the NextFlex Innovation Day further strengthens the event’s position as the definitive North American meeting point for the community. “Electronics RESHAPED USA has firmly established itself as the premier event for our industry in North America, consistently selling out year after year. This is now the home of Printed, Additive, and Hybrid Electronics. By bringing the show to the heart of Silicon Valley for the firs...

13 January 2026

What Is Electronics Encapsulation?

Electronics encapsulation refers to the process of enclosing and protecting electronic components, circuits, or chips in a durable material or “package.” The encapsulating material (sometimes called a molding compound or potting compound) serves as a barrier against environmental factors like moisture, dust, and harsh chemicals, and shields the device from mechanical stress and vibration. Over the decades, encapsulation approaches have evolved significantly. Historically, hermetic encapsulation (a method of sealing sensitive electronic components inside airtight metal or ceramic enclosures) was common, as it completely blocked moisture and gases. This was especially important in aerospace or military-grade devices [1]. Since the 1970s, the industry has shifted toward polymer-based plastic encapsulation due to its low cost, ease of processing, and high throughput. Today, encapsulating components usually involves applying polymer resins (epoxies, silicones, polyurethanes, etc.) using automated dispensing, molding, or conformal coating systems. Common types of encapsulation Potting electronics Schematic of an encapsulated PCB assembly, adapted from © Hu C., et al ., CC BY 4.0 In the context of electronics and semiconductors, potting and encapsulation are often used interchangeably. Potting is an encapsulation process where an entire electronic assembly or a larger section of a circuit is placed into a mold (often referred to as a “pot”) and then filled with a potting material ...

25 February 2026

Time To Book Your Spot

MicroLED Connect and AR/VR Connect 16 & 17 September 2026 | High Tech Campus, Eindhoven, Netherlands MicroLED Connect and AR/VR Connect are the most important dedicated conferences and exhibitions in these fields still taking place this year, bringing together the entire industry and applied research community from around the globe. 👉Organised by TechBlick and MicroLED Association 👉Supported by Optica, EPIC Photonics, and Karl Guttag 👉375+ Participants 👉25+ Exhibitors 👉50+ Talks 👉8 Masterclasses 👉3 Tours 👉And a year-round program of curated online events A Look Back to 2025.

Significant Growth in MicroLED Connect and AR/VR Connect MicroLED Connect and AR/VR Connect 2025 was a huge success registrating over 30% YoY growth. The program was world-class, featuring the likes of Google, Jade Bird Display, Lynx, Avegant, ASML, Swave Photonics, Brilliance RGB, Aledia, Mojo Vision and many more. The participation was excellent too, including Apple, Meta, GoogleSamsung, Samsung Displays, Tianma, Sony, ASML, Huawei, Applied Materials, Bosch, Sensortec, GlobalFoundries, Lam Research, Thales, BAE Systems, Anduril Industries, Nokia, EssilorLuxotticaValeo, Garmin, ams-OSRAM, Haylo Ventures, ITEC B.V., Jabil Optics, Fielmann Ventures GmbH, Sioux Technologies, and more A Look Back to 2024.

The First Ever MicroLED Onsite Conference & Exhibition MicroLED Connect 2024 was a huge success with superb participation and fantastic customer feedback - despite the ups and downs o...

18 February 2026

Printed Electronics in Mountain View, California

When: 10 & 11 June 2026 Where: Computer History Museum, Mountain View, California Register before 15 March 2026 for early bird rates The Largest and Most Important Additive Electronics Show in North America! This is the most important and the largest conference and exhibition in North America dedicated to additive, printed, flexible, hybrid, wearable, stretchable, soft electronics. Exhibition floor : Almost sold out. Agenda: Shaping up to be our strongest yet. Featuring: NextFlex Innovation Days Co-locating: Wearables RESHAPED Exhibition Floor Almost Sold Out The exhibition floor is almost sold out with over 90% of the available spots booked. Act now and book your place! Visit here to download the info package including detailed pricing and benefits descriptions. Tom Keenan will also be your primary point of contact (tom@techblick.com) The Only Truly Global Package Worldwide Our packages are the only truly global option, combining the opportunity to exhibit in the USA and Europe with year-round global digital marketing and engagement. The key benefits include: Onsite exhibition (California and/or Berlin shows) 2 or more full onsite conference & exhibition passes 6 or more annual online passes Onsite talk (silver and gold packages only) Online talk Email marketing Social media support Virtual booth...

13 January 2026

Conductive Technologies | Engineering Functionality: The Power of Sensors in Modern Applications

To watch this presentation in full, please purchase TechBlick Annual Pass at https://www.techblick.com/registration and login to TechBlick platform https://app.swapcard.com/event/techblick Engineering Functionality: Sensors Sensors are at the heart of modern technology - integrated into devices we use every day to enhance healthcare, fitness, safety, and comfort. From monitoring vital signs to enabling smart industrial systems, sensors are transforming the way we interact with the world. Depending on the application, sensors come in many forms, each with its own materials, requirements, and performance considerations. Below are a few examples of sensors that are key to next-generation sensor innovation. Biosensors & Electrochemical Sensors: Measure biological and chemical reactions by generating signals proportional to analyte concentration. PTC Heaters: Regulate temperature through self-limiting properties that enhance safety and efficiency. Temperature Sensors: Monitor and maintain optimal conditions using precise electrical signals. We are Exhibiting in California, USA. Visit our booth at the TechBlick event on 10-11 June 2026 . Contact us for your special discount coupon to attend These sensors find use across wearable , diagnostic , and industrial applications, each with distinct design and material needs: Wearables Flexible and stretchable materials Stretchable inks Adhesive layers (for housing-to-patch or multilayer adhesion) Conductive skin contact layers Dia...

13 January 2026

Transparent Touch Applications Using Pedot. Printed Circuits For Flexible Hybrid Electronics

Printed electronics often involve touch applications on flexible transparent films, which creates a demand for transparent conductive materials. Integration of ICs enables the control of capacitive touch functionality, combined with serial communication protocols such as I2C or USB. This allows for much smaller and more efficient connections than traditional solutions using bulky cables. DoMicro is capable of making Flexible Hybrid Electronic touch applications with screen-printed transparent PEDOT electrodes, inkjet printed silver circuitry and Anisotropic Conductive Adhesive ( ACA) bonded components. This paper focusses on the integration processes of printed transparent conductive polymer polyethylene dioxythiophene (PEDOT:PSS). Human machine interfaces and control displays should be easy to understand for the operator. Highlighting essential information depending on mode or status of the equipment creates a focussed and minimal atmosphere without distraction. Visual appearance and coloured feedback of touch icons by RGB controlled backlight LED’s is featured by transparent capacitive touch technology in Flexible Hybrid Electronics (FHE) circuitry. A FHE-Touch foil integrated with a FPCA-LED assembly enables a fully flat, flexible interface system that can be integrated in curve products and surfaces. Touch icon buttons can be completely hidden or made invisible when backlight is switched off. Figure 1 - User interface by Metafas Application demonstrator Figure 1 shows a...